Active 3D Printers How?

Speaking of 3D printers often people usually think of a complex printing process. But not so. There are many interesting things around the creation of a 3D object from the printer. Here is the mechanism of action of 3D printers in the consumer level. Note that you must use to print 3D images.Inputs are plastic fibers, plastic adhesive output3D printers users will choose two types of inputs: Acrylonitrile Butadiene Styrene (ABS) and polylactic acid (PLA resin). Some printers only ABS, some others use both. Plastic materials are fibrous inputs, width 1,75mm or 3mm.

.jpg)

ABS plastic is often used to create Lego. This is the origin of chemical resins, activated at high temperature. PLA resin is a natural origin, such as corn and sugarcane, hard and shiny ABS. In addition to use as input for 3D printers, plastic PLA also be applied to the production of biodegradable packaging.

Plastic fiber used for 3D printers can cost quite expensive. MakerBot firm sold 2.2 pounds (990 grams) of plastic PLA fiber costs $ 48 (960,000 contracts). If looking to buy on eBay will cost cheaper by half. The company estimated 990 grams of plastic fibers are 392 printable chess.

Plastic fiber costs will be reduced if the 3D printing machines became popular and plastic fibers are produced on a large scale. There is another way to reduce input costs as you use plastic fiber molding machine. You put plastic materials recycled or inexpensive plastic molding machines to produce plastic fibers.

.jpg)

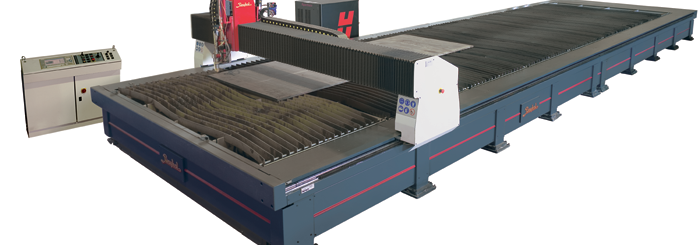

When made of plastic fibers, you put on 3D printers through a division called the print head (print head). The print head is shaped like a box with a nozzle. The actuators will step down early in plastic parts. Before plastic is extruded from a needle printing, plastic fibers must pass through a heat pipe and liquefied. Plastic over metal in the road is only 0.1 millimeters super piece only. Even when exposed to the air, rigid plastic very quickly, tied together to form layers.

ABS should be printed in a hot surface, this also means that the bottom layer of plastic will be slightly rolled up. PLA can also print on plastic surfaces without heat.

Most of the 3D printer has a print head, which is the only object in one color. Want more than one color, one would have to change in the process of printing plastic fibers. There are several types of printers, such as the latest type of printer MakerBot Replicator 2X denoted with 2 printheads. It allows people to print objects with two colors. The company is headquartered in botObjects New York also promises to give the printer model on the market capable of mixing the plastic fibers are to print full-color objects.

Print from front to back, layer overlay

3D printing is a printing technology in layers. Printing surface (often called bed in) and the print head will work together to implement 3-D printing. In form Replicator 2 printer, the print head is held by a suspension system (illustrated below). 2 horizontal metal bar enables the print head moves back and forth horizontally. At the top of this two metal rods attached to two other bars vertically, allowing the print head forward and backward movement vertically. Thanks to the suspension, the print head can move up and down to create 3-dimensional objects.

.jpg)

A printer model called 3D printing RepRaps have relatively different from the print bed RepRaps Replicator 2. moving up and down, backward and forward, while the print head moves only horizontally. DeltaMaker printer models have print heads 3-dimensional motion.

3D printing process can take place in minutes, hours or even days depending on the size and weight of the product. For example, recently a number of artists have used the printer to print the Type A Machines sculpture dragon head size 3 x 3 x 2.4 m. They had to take up to 2 months to complete work on.

.jpg)

3D printers are not only in plastic

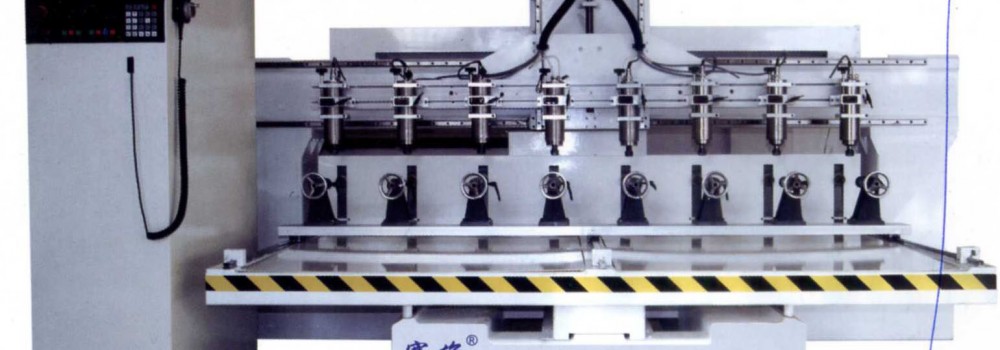

3D printers are not always used in the same material. The professional 3D printers capable of creating high-quality products from diverse materials. At the workshop, Shapeways, a 3D printing machines large size creates multiple products simultaneously. Raw materials not limited to ABS and PLA. It may be made of brass, ceramic, steel and other plastics 5.

Some types of 3D printers use laser molding technology, which is used to mount the piece laser materials together. A number of patents on laser casting will expire next year, paving the way for mass production of 3D printers for consumers.

Form1 FormLabs laboratory is a sample printer uses non-traditional printing technology will soon be the most advanced commercialized. Printers and printer metal hybrid (between traditional print and non-traditional) will be the next device available on the consumer market.

According Vnreview

Layer by layer, 3D printers can create objects from sintered plastic material. VnReview like to introduce to you the process of creating an object of 3D printers, along with cutting-edge printing technology will soon be commercialized in the future. Speaking of 3D printers often people usually think of a complex printing process. But not so. […]

ok

No comments yet.